QLD - Brisbane | Gold Coast | Sunshine Coast | Rockhampton | Mackay | Townsville | Cairns

NSW - Sydney | Regional & Northern NSW

Installation Manual - Construction Guide (standard)

This Installation Manual is designed as a guide for first time users of the ABSpanel system, and gives detailed outline of construction techniques, tools and tips used to erect the panels.

This guide is current at July 2017. ASBSpanel has taken all reasonable care in producing this guide, but ABSpanel makes no representations or warranties, express or implied, as to the accuracy, reliability or completeness of the guide, and disclaims all liability, direct or indirect (and whether or not arising out of the negligence, default or lack of care of ABSpanel) for any loss or damage (whether foreseeable or not) suffered by the recipient or any other person arising out of, or in connection with, any use or reliance by any of them on the guide. Liability which cannot legally be excluded is limited to the maximum extent possible.

Information including acoustic and fire rating has been sourced from recognised third parties. Systems, standards and building codes are subjected to change. It remains the responsibility of the building designer to verify these systems are suitable for the particular requirements of any given project.

This guide is current at July 2017. ASBSpanel has taken all reasonable care in producing this guide, but ABSpanel makes no representations or warranties, express or implied, as to the accuracy, reliability or completeness of the guide, and disclaims all liability, direct or indirect (and whether or not arising out of the negligence, default or lack of care of ABSpanel) for any loss or damage (whether foreseeable or not) suffered by the recipient or any other person arising out of, or in connection with, any use or reliance by any of them on the guide. Liability which cannot legally be excluded is limited to the maximum extent possible.

Information including acoustic and fire rating has been sourced from recognised third parties. Systems, standards and building codes are subjected to change. It remains the responsibility of the building designer to verify these systems are suitable for the particular requirements of any given project.

1. Getting Started

|

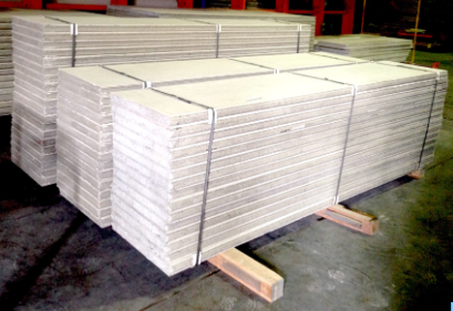

ABSpanel is a lightweight, composite construction panel.

The ABSpanel Panel System consists of a low density core, containing a mixture of Portland cement, Polystyrene beads, water and fire retardant compounds. The mixture is then encased between 2 layers of 6mm Fibre reinforced Cement sheeting, and allowed to cure. The resulting structure has a mass of only 39 kg/m2 for t he 50mm panel and 54kg/m2 for the 75mm panel. Two men can manoeuvre the panels into position and install the system with little difficulty. ABSpanels are glued along the edges and fitted together. Fasteners are fixed into place and then panels are simply stopped with conventional plastering techniques. |

They can be painted with a standard 3 coat system for a smooth internal look, or have hi-build polymer texture applied for an extra rough Tuscan feel. The panels will accept almost any finishes, from water based and enamels paints through to polymers to cement render coatings.

The ABSpanel fits into a prepared rebate in the concrete slab. The rebate is 75mm wide and 100mm deep and is formed along the external edge of the slab.

Several methods can be utilised to construct the rebate, from a timber former to a specially constructed steel form. Your concreter will advise you on the best solution for your particular job. For this exercise we will be using the ABSpanel edge former.

The footings, slab and concrete mix should be designed by your engineer to suit your particular conditions. Pour the concrete, finish to the required surface finish and allow to cure as required. Strip the edge forms approximately 24 hours after it has set thoroughly. Allow the concrete to cure a further 48 hours minimum.

You are now ready to install ABSpanel into the perimeter rebate.

The ABSpanel fits into a prepared rebate in the concrete slab. The rebate is 75mm wide and 100mm deep and is formed along the external edge of the slab.

Several methods can be utilised to construct the rebate, from a timber former to a specially constructed steel form. Your concreter will advise you on the best solution for your particular job. For this exercise we will be using the ABSpanel edge former.

The footings, slab and concrete mix should be designed by your engineer to suit your particular conditions. Pour the concrete, finish to the required surface finish and allow to cure as required. Strip the edge forms approximately 24 hours after it has set thoroughly. Allow the concrete to cure a further 48 hours minimum.

You are now ready to install ABSpanel into the perimeter rebate.

2. Tools List

The following equipment is recommended before construction is commenced:

- 9” circular saw with masonry blade

- Reciprocating saw

- Industrial handheld router *

- Electric planner

- Pipe clamps that span the length of the building *

- Small pipe clamps *

- Bracing material for the walls *

- Rotary Hammer drill (Hilti) with masonry bits if using tie down rods only

- Grinder

- Dumpy level

- Coil gun or Paslode gun

- Hitachi Easy Bevel

- Roofing square

3. Installing ABS Panel

|

1. Clean slab (rebate)

The rebate in the slab is cleaned of any dirt and loose material, washed with clean water and allowed to dry. 2. Establish the layout of your panels It is important that the layout of the panels is established prior to placing and cutting the panels. The first panel should be placed square to a corner, and then the second should be placed at 90 degrees to the first. This will create a stable corner with which to start. |

3. Your starting point

Stand the first panel, apply adhesive to the butt edge, then stand the second panel at 90 degrees to the first. Gently tap the panels together, prop firmly and allow to cure whilst preparing the next panel.

4. Bracing

Bracing the panels in the correct alignment is critical. Care should be taken that the panels are both true and vertical.

Stand the first panel, apply adhesive to the butt edge, then stand the second panel at 90 degrees to the first. Gently tap the panels together, prop firmly and allow to cure whilst preparing the next panel.

4. Bracing

Bracing the panels in the correct alignment is critical. Care should be taken that the panels are both true and vertical.

5. Cutting windows

Two methods can be employed for penetration for windows and doors. Firstly, the panels can be cut to size prior to installation or secondly cut out after the panels are positioned.

6. Header panels

Place header panels into position and fix in place.

Two methods can be employed for penetration for windows and doors. Firstly, the panels can be cut to size prior to installation or secondly cut out after the panels are positioned.

6. Header panels

Place header panels into position and fix in place.

7. Internal walls

Internal walls are set into light gauge track fastened to the slab. Adhesive is placed on the bottom as well as the rebate of the panels. The panels are then fixed as per the external walls.

Continue to place and secure panels in their correct position until all panels are installed.

Internal walls are set into light gauge track fastened to the slab. Adhesive is placed on the bottom as well as the rebate of the panels. The panels are then fixed as per the external walls.

Continue to place and secure panels in their correct position until all panels are installed.

9. Roof Trusses

Roof trusses can be either steel or timber in construction and should be designed by a qualified engineer. The method of installing the trusses is traditional, and no special tools are required for this task.

Roof trusses can be either steel or timber in construction and should be designed by a qualified engineer. The method of installing the trusses is traditional, and no special tools are required for this task.

10. Window installation

Install windows using expanding foam as a filling and adhesive. This ensures a permanent, draft proof fitting that is paintable, can be rendered over or plastered over.

Install windows using expanding foam as a filling and adhesive. This ensures a permanent, draft proof fitting that is paintable, can be rendered over or plastered over.

|

11. Battens installation

Install battens to allow services to be installed. Either steel or treated timber batter battens can be used. If timber battens are used, the method of insect protection should be considered. 12. Adding services Install battens to allow services to be installed. Either steel or treated timber batter battens can be used. If timber battens are used, the method of insect protection should be considered. Services can also be installed in specially constructed panels that have conduits strategically placed internally. |

|

13. Second storey construction

For 2 storey construction, the use of either pole plate or beam and post or a combination of both can be used. The second story walls are installed exactly the same as the ground floor. Your engineer will need to design any ancillary support structures required for your particular project |

16. The finished project

Your finished project will be a home that you will be proud of for many rears to come, the external walls will also take architectural stone finishes, corbels and dado rails to make your home stand out from the crowd.

Your finished project will be a home that you will be proud of for many rears to come, the external walls will also take architectural stone finishes, corbels and dado rails to make your home stand out from the crowd.

4. Handling & Installation Guidelines

1. Introduction

In this document, ABSpanel will outline handling issues to be addressed during the panel installation. However, there is no replacement for common sense.

2. Panel Delivery and layout

When ABSpanels are delivery to site, it is recommended that the panels be taken from the truck to the appropriate work area. This will reduce the amount of double handling and product damage.

3. Layout Drawings

When layout drawings are provided, then the panels shall be installed as detailed on the drawings. The project engineer shall be consulted for prior approval of any variations. Panels should not be cut unless indicated on the Layout Drawings.

4. Site Preparation

The work area should be kept clear of waste and unnecessary equipment, and panels arranged to allow easy, unobstructed access to work area (eliminate possible tripping).

All preparation and accessories, such as brackets, fixings, adhesives, packers, surface treatments (waterproof membranes etc) should be accessible, installed or completed prior to lifting the panels.

5. Lifting

Whenever possible, panels are to be lifted and transported to the workplace using approved lifting devices.

When lifters are to be used to lift and move the panels, ABSpanel recommends lifting them with your legs, keeping your back straight, and stabilising the panel with your shoulder and/or free hand. It is not recommended that the panel be held clear of the lifter’s body causing undue stress to the person lifting the panel.

During installation, persons not involved in the lifting and fixing process should remain clear of the work area, and make installlers aware of their presence before approaching.

IMPORTANT: Ensure every member of the installation team is aware of their role and that there is a nominated team leader.

6. Bracing

At all times, the panel should be supported by a person other than the person installing the fixings. Never release a panel until all fixings are installed and the panel is secure.

In this document, ABSpanel will outline handling issues to be addressed during the panel installation. However, there is no replacement for common sense.

2. Panel Delivery and layout

When ABSpanels are delivery to site, it is recommended that the panels be taken from the truck to the appropriate work area. This will reduce the amount of double handling and product damage.

3. Layout Drawings

When layout drawings are provided, then the panels shall be installed as detailed on the drawings. The project engineer shall be consulted for prior approval of any variations. Panels should not be cut unless indicated on the Layout Drawings.

4. Site Preparation

The work area should be kept clear of waste and unnecessary equipment, and panels arranged to allow easy, unobstructed access to work area (eliminate possible tripping).

All preparation and accessories, such as brackets, fixings, adhesives, packers, surface treatments (waterproof membranes etc) should be accessible, installed or completed prior to lifting the panels.

5. Lifting

Whenever possible, panels are to be lifted and transported to the workplace using approved lifting devices.

When lifters are to be used to lift and move the panels, ABSpanel recommends lifting them with your legs, keeping your back straight, and stabilising the panel with your shoulder and/or free hand. It is not recommended that the panel be held clear of the lifter’s body causing undue stress to the person lifting the panel.

During installation, persons not involved in the lifting and fixing process should remain clear of the work area, and make installlers aware of their presence before approaching.

IMPORTANT: Ensure every member of the installation team is aware of their role and that there is a nominated team leader.

6. Bracing

At all times, the panel should be supported by a person other than the person installing the fixings. Never release a panel until all fixings are installed and the panel is secure.

5. Recommended Panel Handling Guidelines

|

|

|

|

- Lifting handles are to be positioned so arms are straight when panel is lifted

- Bend your hips and knees and straighten your legs to lift

- Use your feet to change direction, taking small steps to place panel into position

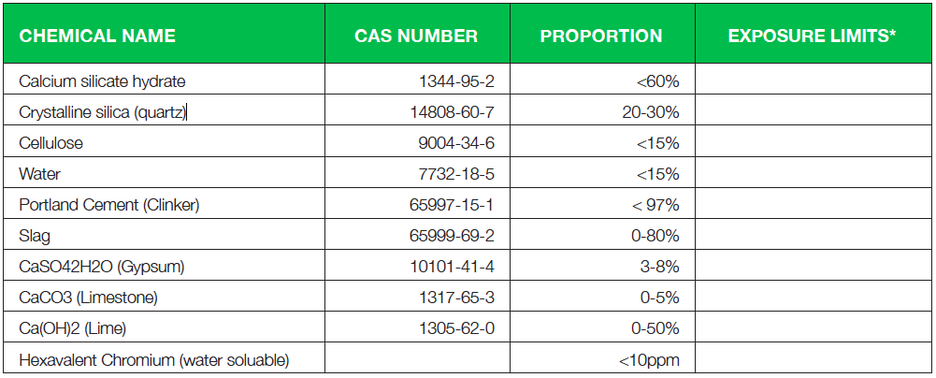

6. Material Safety Data Sheet

IMPORTANT NOTICE:

This Material Safety Data Sheet (MSDS) is issued by the Supplier in accordance with National Occupational Health and Safety Commission (NOHSC) guidelines. As such, the information in it must not be altered, deleted or added to. The Supplier will issue a new MSDS when there is a change in product specifications and/or NOHSC guidelines/regulations. The Supplier will not accept any responsibility for any changes made to its MSDS by any other person or organisation.

This Material Safety Data Sheet (MSDS) is issued by the Supplier in accordance with National Occupational Health and Safety Commission (NOHSC) guidelines. As such, the information in it must not be altered, deleted or added to. The Supplier will issue a new MSDS when there is a change in product specifications and/or NOHSC guidelines/regulations. The Supplier will not accept any responsibility for any changes made to its MSDS by any other person or organisation.

Product Name: ABSpanel

Applicable In: Australia

Manufacturer's Product Code: Not Applicable

UN Number: None Allocated

Dangerous Goods Class & Subsidiary Risk: None Allocated

Hazchem Code: None Allocated

Poisons Schedule Number: None Scheduled

Physical Description/Properties: Lightweight concrete panel

Appearance: Grey flat sheets sandwiching a 50mm,75mm 0r 100mm thick polystyrene and cement mix

Boiling Point (oC): Not Determined

Melting Point (oC): Not applicable

Vapour Pressure: Not Determined

Specific Gravity (H20=1): 1.3 to 1.7

Flashpoint: Not Applicable

Flammability Limits: Not Flammable

Solubility In Water: Not Applicable

Use: Used as external & internal cladding for residential housing, commercial walling, industrial buildings and flooring. Also for inter-tenancy, FRL, party and any walling system for the above for load bearing and non load bearing wall applications.

Applicable In: Australia

Manufacturer's Product Code: Not Applicable

UN Number: None Allocated

Dangerous Goods Class & Subsidiary Risk: None Allocated

Hazchem Code: None Allocated

Poisons Schedule Number: None Scheduled

Physical Description/Properties: Lightweight concrete panel

Appearance: Grey flat sheets sandwiching a 50mm,75mm 0r 100mm thick polystyrene and cement mix

Boiling Point (oC): Not Determined

Melting Point (oC): Not applicable

Vapour Pressure: Not Determined

Specific Gravity (H20=1): 1.3 to 1.7

Flashpoint: Not Applicable

Flammability Limits: Not Flammable

Solubility In Water: Not Applicable

Use: Used as external & internal cladding for residential housing, commercial walling, industrial buildings and flooring. Also for inter-tenancy, FRL, party and any walling system for the above for load bearing and non load bearing wall applications.

NOTE:

Some products are sealed with acrylic sealer and/ or coated with acrylic coatings. The proportion of these propriety coatings does not exceed 1%. All ingredients may contain crystalline silica. This product does not contain asbestos or asbestiform fragments. Cellulose comes from wood pulp.

HEALTH HAZARD INFORMATION

STATEMENT OF HAZARDOUS NATURE: This product is classified as hazardous according to the criteria of the National Occupational Health and Safety Commission (NOHSC).

HEALTH EFFECTS

ACUTE

Swallowed: Unlikely under normal conditions of use, but swallowing the dust from this product may result in abdominal discomfort.

Eye: The dust from this product may irritate the eyes causing watering and redness.

Skin: The dust from this product, particularly in association with heat and sweat, may cause irritation, but it is not absorbed through the skin.

Inhaled: The dust may cause irritation of the nose, throat and lungs.

CHRONIC

Inhaled: Repeated exposure to the dust may result in increased nasal and respiratory secretions and coughing. Because of the presence of respirable quartz (crystalline silica), repeated and prolonged exposure to high dust levels may result in silicosis and an increased risk of lung cancer. The International Agency for Research on Cancer (IARC) has evaluated crystalline silica as " Group 1 - Carcinogenic to humans".

Special Note: Based on limited animal research, it is possible that repeated inhalation of cellulose fibre dust over time may lead to inflammation and scarring of the lung in humans. Measures taken to protect against crystalline silica dust will also be adequate for preventing health effects from cellulose. See ‘Precautions for Use’.

FIRST AID

Swallowed: Rinse mouth and give plenty of water to drink. If symptoms persist seek medical attention.

Eye: Flush thoroughly with flowing water for at least ten minutes. If symptoms persist, seek medical attention.

Skin: Wash thoroughly with soap and water. If any irritation persists seek medical advice.

Inhaled: Remove too fresh air. Seek medical advice if symptoms persist.

Advice to Doctor: Treat symptomatically.

PRECAUTIONS FOR USE

EXPOSURE

Standards: None Allocated from NOHSC. There is no specific standard for Fibre Cement but the standards for calcium silicate containing <1.0% crystalline-silica and crystalline-silica (quartz) should apply. Respirable Silica-crystalline: 0.2 mg/cubic metre time-weighted average (TWA) Inspirable calcium silicate dust: 10.0 mg/ cubic metre time-weighted average (TWA). Cellulose (paper fibre): 10 mg/cubic metre (TWA) measured as inspirable dust.

Engineering Controls: During the normal installation of the product, no significant dust problem should occur. If, however, the product is cut or machined, the following precautions should be applied: Hand tools should be used for cutting, drilling or sanding. If the use of power tools is necessary, the power tools must be fitted with efficient and well maintained dust extraction devices. Work areas should be well ventilated and cleaned at least daily. Dust must be removed by vacuum cleaners fitted with HEPA filters, by sweeping after dampening, or by hosing if approved waste water collection systems are available.

Manufacturers’ Recommendations: Keep exposure of dust as low as practicable.

PERSONAL PROTECTION

Skin Protection: Loose comfortable clothing should be worn.

Approved personal protective equipment should conform with the relevant standards published by Standards Australia and/or Standards New Zealand. Direct skin contact should be avoided by wearing long sleeved shirts andlong trousers, a cap or hat, and gloves (standard duty leather or equivalent AS 2161). Work clothes should be washed regularly and separately from other clothes.

Eye Protection: Ventilated non-fogging goggles (dust resistant AS/NZS 1336) should be worn when working in a dusty environment.

Respiratory Protection: An approved particulate respirator (AS/NZS 1715 and 1716) should be worn when working in a dusty environment. Respirators should be correctly fitted, maintained in good condition, and kept in clean storage when not in use. Replaceable filters and cartridges should be replaced regularly in accordance with the manufacturers’ guidelines and AS/NZS 1715 and 1716.

Personal Hygiene: Wash face and hands before eating or drinking after handling this product.

Flammability: Avoid a build-up of dust and keep all storage and work areas well ventilated.

SAFE HANDLING INFORMATION

Storage and Transport: This product should be stored in a dry area. No special transport requirements are necessary.

Spills and disposal: Dust and waste should be cleaned up by bagging, wet sweeping and/or vacuuming. Waste should be placed into containers and disposed of as trade waste in accordance with local waste disposal authority guidelines.

Fire/explosion hazard: The product is non flammable. Extinguish with Carbon dioxide, water, foam or dry chemical as for surrounding materials.

Smoking and Other Dust: Inhalation of airborne particles from other sources, including those from cigarette smoke, may increase the risk of lung disease. Absolute Building Supplies recommends that all storage and work areas should be non-smoking zones, and other airborne contaminants be kept to a minimum.

ECOLOGICAL INFORMATION

The ingredients for this product are not harmful and no adverse environmental effects would be expected if this product were accidentally released in the water or soil. No harm to fish or wildlife would be caused by this product. It is recommended that all off cuts and waste be disposed of properly and be kept clear of areas leading to drains and waterways.

Whilst the information contained in this document is based on data which, to the best of our knowledge, was accurate and reliable at the time of preparation, no responsibility can be accepted by us for errors and omissions. The provision of this information should not be construed as a recommendation to use any of our products in violation of any patent rights or in breach of any statute or regulation. Users are advised to make their own determination as to the suitability of this information in relation to their particular purposes and specific circumstances.

Since the information contained in this document may be applied under conditions beyond our control, no responsibility can be accepted by us for any loss or damage caused by any person acting or refraining from action as a result of this information.

Some products are sealed with acrylic sealer and/ or coated with acrylic coatings. The proportion of these propriety coatings does not exceed 1%. All ingredients may contain crystalline silica. This product does not contain asbestos or asbestiform fragments. Cellulose comes from wood pulp.

HEALTH HAZARD INFORMATION

STATEMENT OF HAZARDOUS NATURE: This product is classified as hazardous according to the criteria of the National Occupational Health and Safety Commission (NOHSC).

HEALTH EFFECTS

ACUTE

Swallowed: Unlikely under normal conditions of use, but swallowing the dust from this product may result in abdominal discomfort.

Eye: The dust from this product may irritate the eyes causing watering and redness.

Skin: The dust from this product, particularly in association with heat and sweat, may cause irritation, but it is not absorbed through the skin.

Inhaled: The dust may cause irritation of the nose, throat and lungs.

CHRONIC

Inhaled: Repeated exposure to the dust may result in increased nasal and respiratory secretions and coughing. Because of the presence of respirable quartz (crystalline silica), repeated and prolonged exposure to high dust levels may result in silicosis and an increased risk of lung cancer. The International Agency for Research on Cancer (IARC) has evaluated crystalline silica as " Group 1 - Carcinogenic to humans".

Special Note: Based on limited animal research, it is possible that repeated inhalation of cellulose fibre dust over time may lead to inflammation and scarring of the lung in humans. Measures taken to protect against crystalline silica dust will also be adequate for preventing health effects from cellulose. See ‘Precautions for Use’.

FIRST AID

Swallowed: Rinse mouth and give plenty of water to drink. If symptoms persist seek medical attention.

Eye: Flush thoroughly with flowing water for at least ten minutes. If symptoms persist, seek medical attention.

Skin: Wash thoroughly with soap and water. If any irritation persists seek medical advice.

Inhaled: Remove too fresh air. Seek medical advice if symptoms persist.

Advice to Doctor: Treat symptomatically.

PRECAUTIONS FOR USE

EXPOSURE

Standards: None Allocated from NOHSC. There is no specific standard for Fibre Cement but the standards for calcium silicate containing <1.0% crystalline-silica and crystalline-silica (quartz) should apply. Respirable Silica-crystalline: 0.2 mg/cubic metre time-weighted average (TWA) Inspirable calcium silicate dust: 10.0 mg/ cubic metre time-weighted average (TWA). Cellulose (paper fibre): 10 mg/cubic metre (TWA) measured as inspirable dust.

Engineering Controls: During the normal installation of the product, no significant dust problem should occur. If, however, the product is cut or machined, the following precautions should be applied: Hand tools should be used for cutting, drilling or sanding. If the use of power tools is necessary, the power tools must be fitted with efficient and well maintained dust extraction devices. Work areas should be well ventilated and cleaned at least daily. Dust must be removed by vacuum cleaners fitted with HEPA filters, by sweeping after dampening, or by hosing if approved waste water collection systems are available.

Manufacturers’ Recommendations: Keep exposure of dust as low as practicable.

PERSONAL PROTECTION

Skin Protection: Loose comfortable clothing should be worn.

Approved personal protective equipment should conform with the relevant standards published by Standards Australia and/or Standards New Zealand. Direct skin contact should be avoided by wearing long sleeved shirts andlong trousers, a cap or hat, and gloves (standard duty leather or equivalent AS 2161). Work clothes should be washed regularly and separately from other clothes.

Eye Protection: Ventilated non-fogging goggles (dust resistant AS/NZS 1336) should be worn when working in a dusty environment.

Respiratory Protection: An approved particulate respirator (AS/NZS 1715 and 1716) should be worn when working in a dusty environment. Respirators should be correctly fitted, maintained in good condition, and kept in clean storage when not in use. Replaceable filters and cartridges should be replaced regularly in accordance with the manufacturers’ guidelines and AS/NZS 1715 and 1716.

Personal Hygiene: Wash face and hands before eating or drinking after handling this product.

Flammability: Avoid a build-up of dust and keep all storage and work areas well ventilated.

SAFE HANDLING INFORMATION

Storage and Transport: This product should be stored in a dry area. No special transport requirements are necessary.

Spills and disposal: Dust and waste should be cleaned up by bagging, wet sweeping and/or vacuuming. Waste should be placed into containers and disposed of as trade waste in accordance with local waste disposal authority guidelines.

Fire/explosion hazard: The product is non flammable. Extinguish with Carbon dioxide, water, foam or dry chemical as for surrounding materials.

Smoking and Other Dust: Inhalation of airborne particles from other sources, including those from cigarette smoke, may increase the risk of lung disease. Absolute Building Supplies recommends that all storage and work areas should be non-smoking zones, and other airborne contaminants be kept to a minimum.

ECOLOGICAL INFORMATION

The ingredients for this product are not harmful and no adverse environmental effects would be expected if this product were accidentally released in the water or soil. No harm to fish or wildlife would be caused by this product. It is recommended that all off cuts and waste be disposed of properly and be kept clear of areas leading to drains and waterways.

Whilst the information contained in this document is based on data which, to the best of our knowledge, was accurate and reliable at the time of preparation, no responsibility can be accepted by us for errors and omissions. The provision of this information should not be construed as a recommendation to use any of our products in violation of any patent rights or in breach of any statute or regulation. Users are advised to make their own determination as to the suitability of this information in relation to their particular purposes and specific circumstances.

Since the information contained in this document may be applied under conditions beyond our control, no responsibility can be accepted by us for any loss or damage caused by any person acting or refraining from action as a result of this information.

For further information on our ABS Panel please contact Absolute Building Supplies on Ph 0437 289282 or email [email protected]

ABOUT

|

CONTACT US

|

|